Ultimate Guide to Choosing the Right Carbide Cutting Inserts for Your Projects

Table of Contents

- Understanding Different Types of Carbide Cutting Inserts for Various Materials

- Key Factors to Consider When Selecting Carbide Cutting Inserts

- The Importance of Insert Geometry in Machining Performance

- How Coatings Affect the Efficiency of Carbide Cutting Inserts

- Best Practices for Tool Maintenance and Longevity of Cutting Inserts

- Enhancing Machining Efficiency: A Data-Driven Analysis of Kennametal CNMG120412-RP KC9125 Carbide Inserts in the Metal Cutting Industry

- FAQS

- Conclusion

- Related Posts

When it comes to precision machining, picking the right tools is a big deal if you really want great results. And honestly, that’s especially true when it comes to Carbide Cutting Inserts. These little components might seem small, but they actually have a huge impact on how efficient, precise, and high-quality your cutting work ends up being.

When it comes to precision machining, picking the right tools is a big deal if you really want great results. And honestly, that’s especially true when it comes to Carbide Cutting Inserts. These little components might seem small, but they actually have a huge impact on how efficient, precise, and high-quality your cutting work ends up being.

At Jinan Terry CNC Tool Limited Company, we totally get how tricky it can be to choose the right Carbide Cutting Inserts for different projects. As one of China’s top exporters of CNC cutting tools, we’re here to help you navigate all the details and find the perfect inserts that match your specific needs. Whether you're aiming to boost productivity or just make those tools last longer, our ultimate guide will give you the know-how to make smarter choices and take your machining game to the next level.

Understanding Different Types of Carbide Cutting Inserts for Various Materials

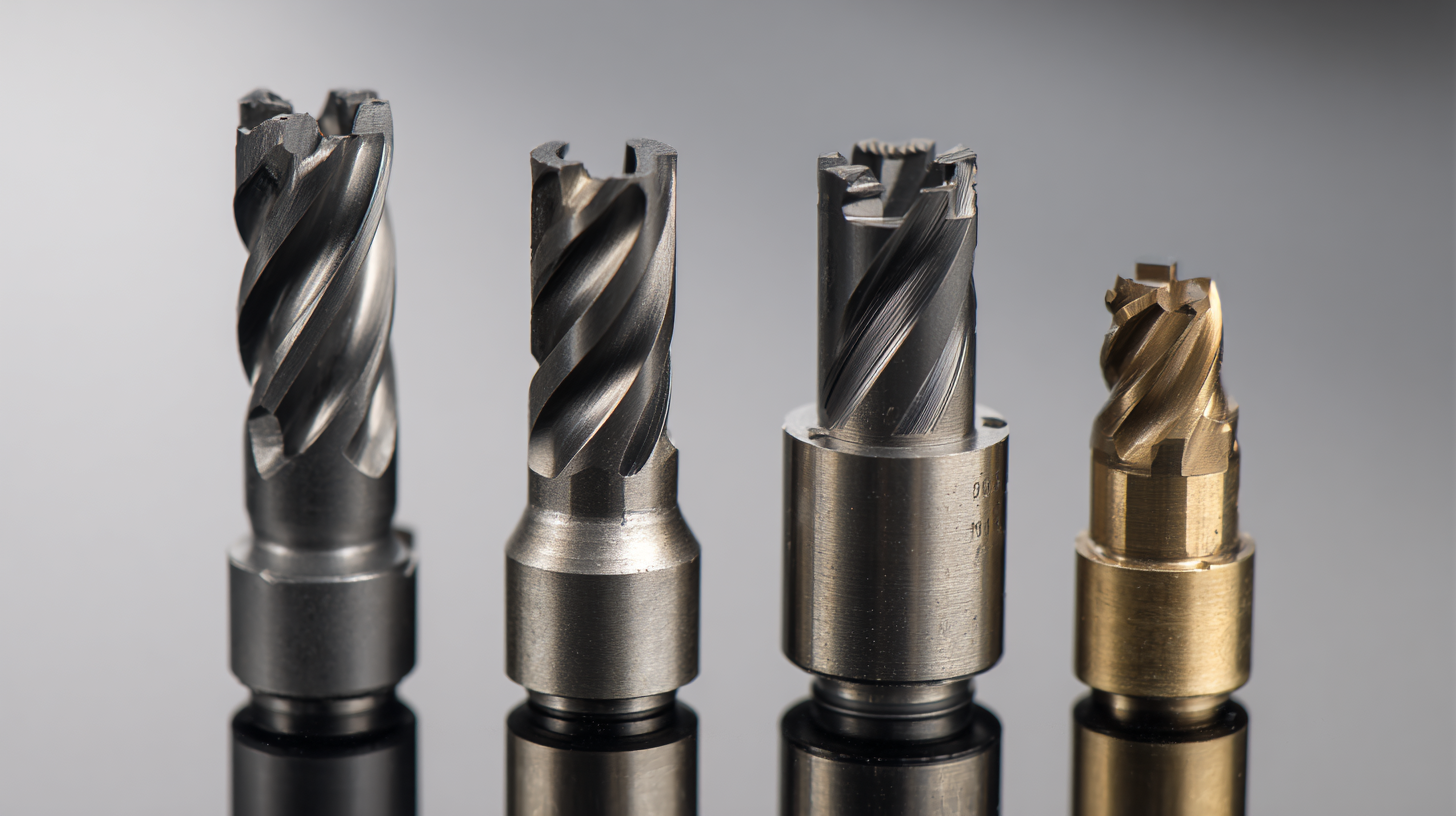

When you're picking out carbide cutting inserts for your projects, it’s really important to understand the different types out there, especially since they’re designed for different materials. These inserts come in all sorts of shapes and coatings, tailored for tasks like drilling, milling, or turning. For example, TiAlN coated inserts are pretty great when you're working on tougher, harder materials, while polycrystalline diamond (PCD) inserts are awesome for abrasive stuff like composites or non-ferrous metals.

**A little tip:** When you're choosing an insert, take a moment to think about what material you'll be working with and what your machining conditions are like. You might need a tougher grade if you're doing continuous cuts or dealing with hardened materials. Also, don't forget to check the American National Standards for the identification system on these inserts — it’s a good way to make sure they’ll fit with your existing tools.

On top of that, it’s worth considering things like the surface finish you need and how fast you want to remove material. From what studies have shown, the shape of the insert and its coating can really make a difference in how well it performs. By taking the time to evaluate these factors, you'll likely see better productivity and longer-lasting tools in your machining projects.

Key Factors to Consider When Selecting Carbide Cutting Inserts

When you're choosing carbide cutting inserts, there are a few key things you want to keep in mind to make sure you're getting the best performance for your project. First off, the material composition really matters—it's what determines how hard the insert is and how well it resists wear. Good-quality carbide is pretty durable and can last a long time, which is awesome for different machining jobs. Also, don’t overlook the shape and angles of the insert; these small details can make cutting smoother and reduce tool deflection, giving you better surface finishes.

Another big factor is the coating on the inserts. Different coatings can really change how well the insert performs—helping to cut down on friction and handle heat better, especially when you're working at higher speeds. Just make sure to pick the coating that matches your material and machining style to keep things efficient.

**Quick tip:** It’s all about testing out different insert setups under real working conditions to see what works best for your specific project. Keep an eye on how the inserts wear over time, and don't be afraid to switch things up if needed. Staying on top of these details can really help optimize your machining processes and lead to better results overall.

The Importance of Insert Geometry in Machining Performance

When you're into machining, you quickly realize that the shape and design of carbide cutting inserts are actually pretty crucial for how well things turn out. The way an insert is shaped and the angles it has can really affect how smoothly it cuts, how long the tool lasts, and how fast you can work. For example, inserts with sharp edges are great for finishing touches—they help give a smoother surface. On the other hand, sturdier, more robust insert designs are better suited for those roughing jobs, where removing large amounts of material is the priority over perfect finish.

So, a good tip when choosing an insert is to think about what you actually need for your specific project. What kind of material are you cutting, and what kind of finish are you aiming for? It’s usually smart to go with inserts that have positive rake angles—it helps cut down on the force needed, which can make your tool last longer and stay more stable. Also, don’t forget about chip control. Picking an insert shape that helps chips flow out smoothly can really save you from issues like chip packing and can make your machining way more efficient.

Oh, and one more thing—pay attention to the corner radius of the insert, too. Bigger corner radii tend to be stronger and handle chips better, but they might sacrifice a little precision, especially if you're working with tight tolerances. Finding that sweet spot between durability and accuracy is key to getting the best results, no matter what kind of project you're tackling.

How Coatings Affect the Efficiency of Carbide Cutting Inserts

When you're picking out carbide cutting inserts for machining, it's pretty important to get what impact coatings have. They can really boost how well the inserts perform by making them more resistant to wear and better at handling heat. I read somewhere—like in a 2022 report from the Cutting Tool Engineering Association—that coated carbide inserts can last up to 60% longer, which means less downtime and a lot less money spent overall on machining. Not too shabby, right?

The kind of coating you choose makes a big difference in how effective your inserts are. For example, aluminum oxide (Al2O3) coatings are pretty popular because they’re super hard and handle heat really well—great for dealing with tougher materials. On the other hand, titanium nitride (TiN) coatings are known for reducing friction, so you can run your tools at higher speeds without as much trouble. Interestingly, recent studies show that thicker coatings—especially with TiN—can cut down wear by as much as 30%, compared to uncoated tools, under similar conditions.

And it gets even more interesting with newer coatings like multi-layer or nano-coatings. These are like the supercharged versions that combine different materials' benefits. According to the International Journal of Advanced Manufacturing Technology, multi-layer coatings let the inserts take higher temps and pressures, which means they cut better and leave a nicer finish on the parts. As tech evolves, we keep seeing these innovative coatings really transforming how effective carbide inserts can be, helping industries crank out more and better-quality work. Pretty fascinating stuff, isn’t it?

Best Practices for Tool Maintenance and Longevity of Cutting Inserts

Taking good care of your carbide cutting inserts is pretty important if you want your machining projects to run smoothly and last longer. Honestly, a good practice is to peek at those inserts regularly — check for any signs of wear or damage. Things like chips or a dull edge are pretty clear indicators that it’s time for a replacement. Catching these early can save you from costly downtime and keep your operations ticking along efficiently. Setting up a routine inspection schedule isn’t just about catching problems early; it also helps you keep tabs on how each tool is performing over time, so you know when to swap out the old ones and keep everything consistent.

Another thing that often gets overlooked is cleaning. After you’re done with a cut, give the inserts a quick wipe to remove chips or debris. It might seem small, but it really helps extend their lifespan. Just make sure you’re using the right cleaning methods and products — you don’t want to damage the carbide surface. And when you’re not using them, storing the inserts in a protective case or holder is a smart move to prevent accidental bumps or drops. Following these simple practices can really make a difference — you’ll get more out of your inserts, save some cash, and hopefully get better results in your projects overall.

Enhancing Machining Efficiency: A Data-Driven Analysis of Kennametal CNMG120412-RP KC9125 Carbide Inserts in the Metal Cutting Industry

In the fast-paced metal cutting industry, improving machining efficiency is paramount. The analysis of Kennametal CNMG120412-RP KC9125 carbide inserts showcases their exceptional performance in various applications. Designed specifically for high-speed cutting, these original Kennametal brand tools exhibit remarkable wear resistance, enabling them to maintain their integrity over extended periods. This feature is essential for operations involving steel, stainless steel, cast iron, and nonferrous materials, where durability can make a significant difference in output.

The KC9125 inserts stand out not only for their longevity but also for their stability and security during productive turning. This reliability translates into consistent performance, allowing machinists to achieve high levels of productivity without frequent tool changes. Furthermore, the high toughness and low cutting force required by these inserts make them an excellent choice for workpieces with complex geometries, which often pose challenges in conventional machining processes. With defined applications in ISO and ANSI standards, the Kennametal CNMG120412-RP inserts effectively meet the stringent demands of modern machining environments, driving efficiency to new heights.

FAQS

: Insert geometry is crucial because it directly influences cutting action, impacting surface finish, tool life, and cutting speed. Different geometries are suited for specific tasks, such as finishing or roughing operations.

For finishing tasks, it's best to choose inserts with sharper cutting edges, as they yield smoother surfaces.

Opting for inserts with positive rake angles can help reduce cutting forces, thereby enhancing tool life and stability during machining.

Selecting an insert geometry that supports optimal chip flow can prevent issues like chip packing, thereby increasing overall machining efficiency.

A larger corner radius can improve tool strength and chip management but may compromise precision in tight tolerances. It's vital to balance durability and accuracy based on specific needs.

Regularly inspecting inserts for wear and damage, keeping them clean from chips and debris, and storing them properly in protective cases are key maintenance practices to enhance their lifespan.

Implementing a routine inspection schedule is advisable to track performance, identify wear, and ensure timely replacements to maintain efficiency.

Use suitable cleaning agents and methods that do not damage the carbide surface to keep cutting inserts free from chips and debris after each use.

Proper maintenance ensures optimal performance and longevity of cutting inserts, ultimately saving time and resources and improving project outcomes.

Identifying signs of wear, such as chipping or dull edges, is critical, and you should replace the insert promptly to prevent costly downtime and maintain efficiency in operations.

Conclusion

Hey there! So, in our 'Ultimate Guide to Picking the Right Carbide Cutting Inserts for Your Projects,' we really dive into what you need to know to choose the best inserts for different materials. Honestly, understanding the different types of carbide inserts is super important because their performance can vary a lot depending on what you're working on. Things like what material you're cutting, the speed you're using, and the shape of your tool — all of these really matter if you want to get that perfect finish and keep things running smoothly.

We also talk about how the shape of the insert can make a difference — certain designs can boost your efficiency during cuts. And let’s not forget about coatings! They can really improve how tough the inserts are and help them last longer, plus give you a better surface finish. Oh, and a quick tip — taking good care of your tools and staying on top of maintenance isn’t just about keeping things nice; it actually saves you money and helps you get more done in less time.

At Jinan Terry CNC Tool Limited Company, we're proud to offer a wide variety of top-quality carbide cutting inserts. Our goal? Helping you smash your project goals with less hassle and more success!

Related Posts

-

How to Choose the Best Carbide Insert for Aluminum Machining

-

How to Select the Best Cnc Indexable Carbide Inserts Wnmg for Your Machining Needs

-

7 Best Tips to Maximize the Efficiency of Carbide Tool Inserts

-

How to Choose the Best High Qualiti Insert for Your Project

-

7 Unique Features of Stone Cutting Inserts You Should Know

Blog Tags:

Lila

-

Phone

-

E-mail

-

Skype